component supply

Acrylic Component Supply – Throughout the companies history, we have also supplied acrylic components for a variety of industries. Creating the acrylic elements requires broad industry knowledge and strong customer relationships. As well as consistent, attentive fabrication and design, from our entire in-house team. We continue to supply these acrylic sections into industries such as touring caravans, bespoke lighting, engineering machinery and more.

GLOBALVIEW SYSTEMS – Custom Enclosures

GlobalView Systems design and manufacture marine electronic systems. We were approached for the Super and Mega Yacht sector – To assist in the design and development of custom enclosures.

Also, these enclosures needed to conform to the Safety Of Life At Sea (SOLAS) regulations. As laid down International Maritime Organisation (IMO). Our designs also had to be subjected and pass some of the most rigorous testing available. Testing included a 28 day salt mist test, shock, vibration and finally accelerated heat and cold cycles.

Eventually, these systems would find themselves on many of the most prestigious vessels in the world. With quality and attention to detail paramount.

Caravan shower doors

For 14+ years, we have supplied the touring caravan industry with formed acrylic Shower Doors. These sit into the cubicles of some of the leading brands’ units. This requires precise and consistent fabrication throughout the rollouts.

The shower doors are oven formed in house, from 4mm thick Perspex acrylic. We also fit the brackets and drill the handles. Finally, this component is sent off to be made into a finished cubicle unit.

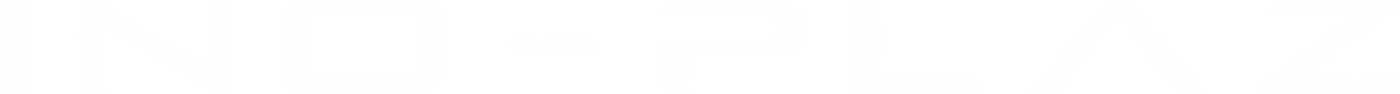

kemps lighting – lighting strips

Bespoke lighting are where Kemps Architectural Lighting leads the way. We were asked to assist in their bespoke lighting collaboration with Studio Fractal. This project was to be installed in the Almere shopping centre in the Netherlands.

This project required lenses for 52 “Light swirls”, 11 designs were created from 1785mm – 7300mm using 25mm clear acrylic. To a depth of 75mm, with a frosted finish applied on three sides and mitred to join sections. Then thermoformed using our in-house formers and set into the steel U channel provided by Kemps Lighting.

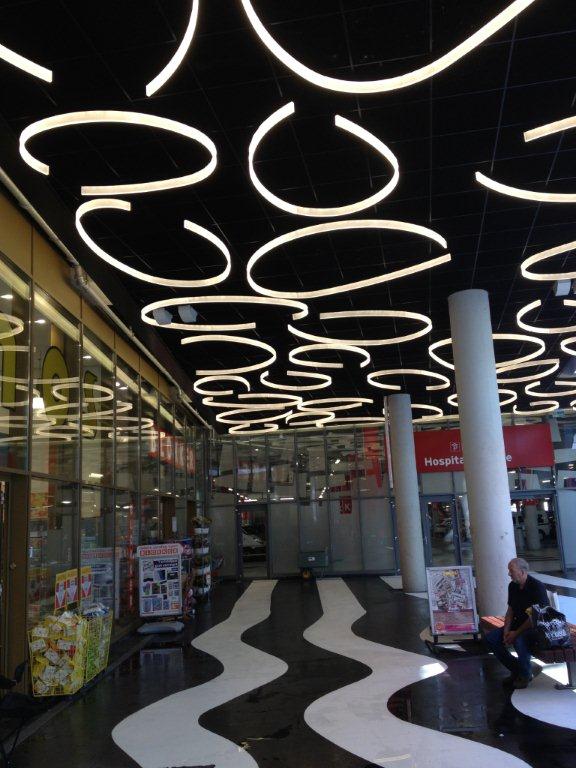

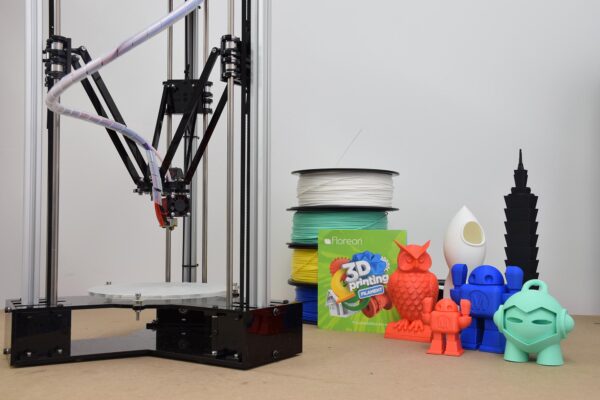

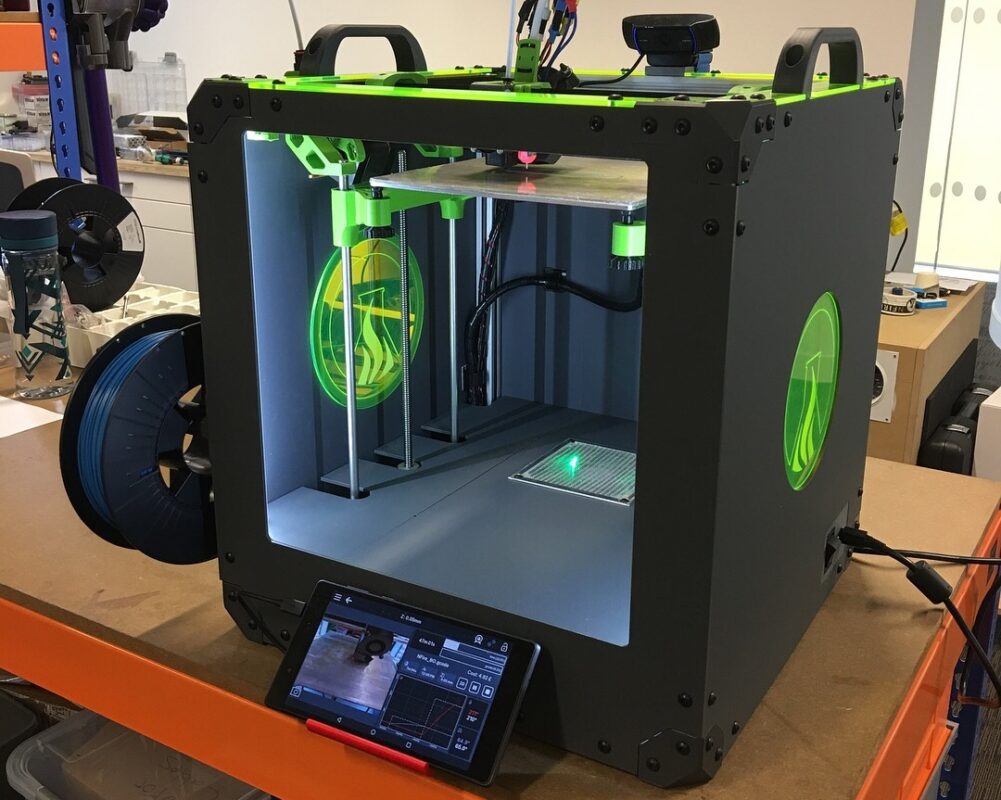

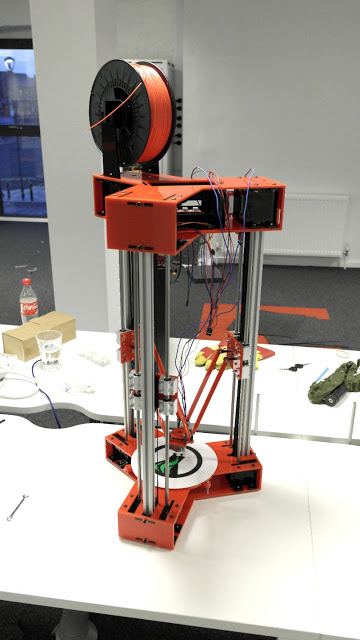

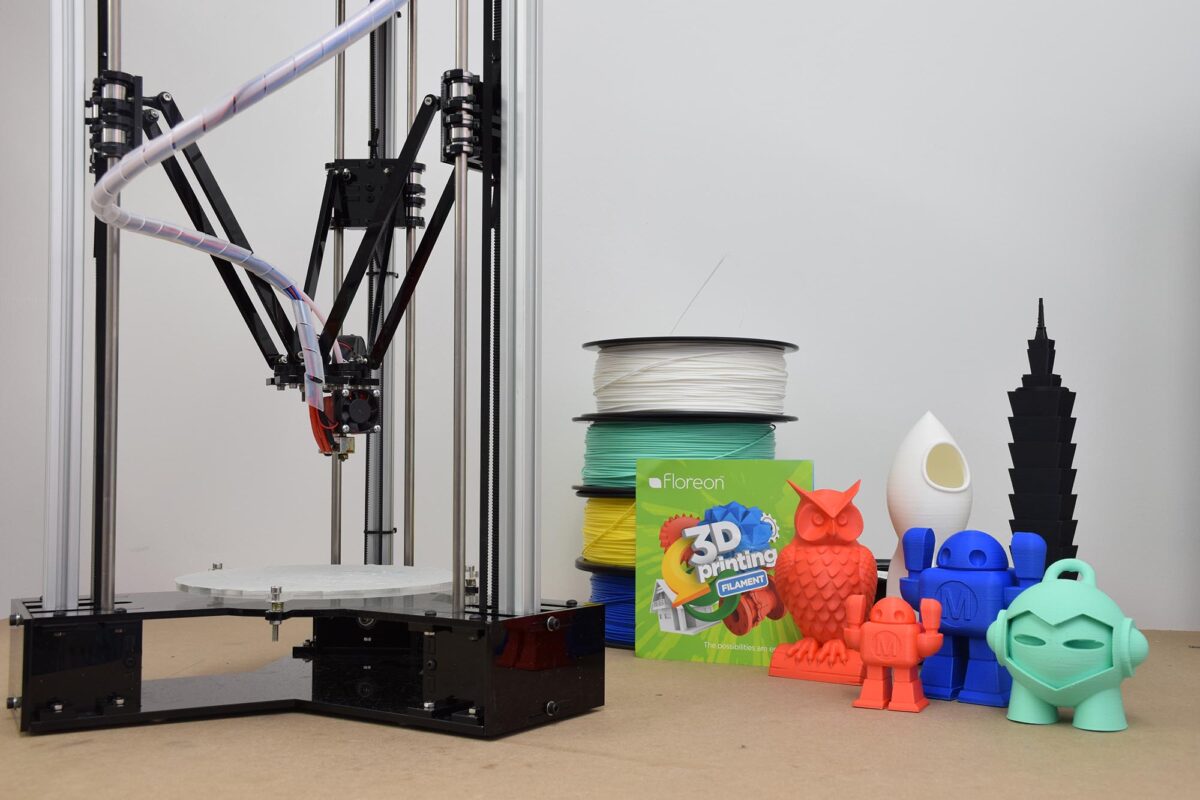

NFire Labs – 3D Printer Covers

NFire Labs specialise in prototyping and the manufacture high quality 3D printers. The machines are modular and can be tailored to each individual requirement.

During the initial design, we were asked to get involved to create acrylic covers and cladding panels. Firstly, we created covers for the early prototypes while it was in its design phase. Then developed this with the product into its final composition. Finally, the finished products are sold to companies all over the world, or rented out to smaller businesses in the local area.